How Out-of-Stock Inventory is Killing Toys’‘R’‘Us

The company’s chief executive has pinpointed the issues facing the company, but the main challenge lies in fixing the problems the ailing toy giant is facing.

Running out of stock is one of the worst things that can happen to a major specialty retailer.

During last year’s holiday season, Toys”R”Us experienced this first hand.

For a company that has built its reputation on carrying the biggest range of toys and baby products, the prevalence of empty shelves has damaged their brand image.

According to a report by the Wall Street Journal, on Black Friday, the retailer’s website was in stock 62% of the time on the 100 top selling toys.

While that’s below the 95% recommended service level due to it being peak sales season, it’s on par with many other retailers. Wal-Mart Stores had a 63% in-stock rate, and Target had a 51% rate.

So What Is The Problem?

Since the company’s founding, Toys“R”Us has been marketing itself as the world’s leading toy and baby products retailer.

While that has allowed them to build themselves a niche in the market when they started the business over 65 years ago, it’s becoming a problem.

Once Toys“R”Us has sold out their most popular toys, there’s no longer any reason for customers to choose them over their competitors, which damages their business image.

Customers of Toys"R"US describe their shopping experience as “the shelves were very empty and it felt like we were shopping leftovers.” One reason for this could be due to the company’s policy of considering stores being in-stock if they had three units of a particular SKU, which in turn leads to shelves looking half empty.

Chief executive David Brandon’s solution to the company’s woes is to “be bulkier.” In a world where everyone’s going for a leaner, “just-in-time” inventory to save on costs, Toys"R"Us’ approach is going against the grain.

But few businesses are stuck in the same catch-22 situation as Toys“R”Us. Their reputation hinges on offering the broadest selection of toys available, so the only way for them to salvage their business image is to increase their stock on hand and go “full and chunky”.

Fuller shelves may not be enough since their target market is turning to internet retailers like Amazon for faster shipping and better customer service. In light of this, for Toys"R"Us to remain competitive, they’ll also need to work on their “clumsy” digital platforms since the trends point to eCommerce being central to a brand’s success.

The second part of the post will be addressing the two biggest issues facing Toys"R"Us:

- They’re always out of stock of popular toys.

- They need to modernize their business model to deal with increased competition.

Product Segmentation

When it comes to dealing with out-of-stock situations for popular items, imposing the same inventory management policy across the board doesn’t work, and that’s when product segmentation comes in.

Product segmentation means that a company would need to look at their various stock keeping units (SKUs) and variants when it comes to setting reorder points.

Basically, a retailer should aim to hold more stock of popular items on hand, and move less popular backroom stock to warehouses to free up more space for top-sellers.

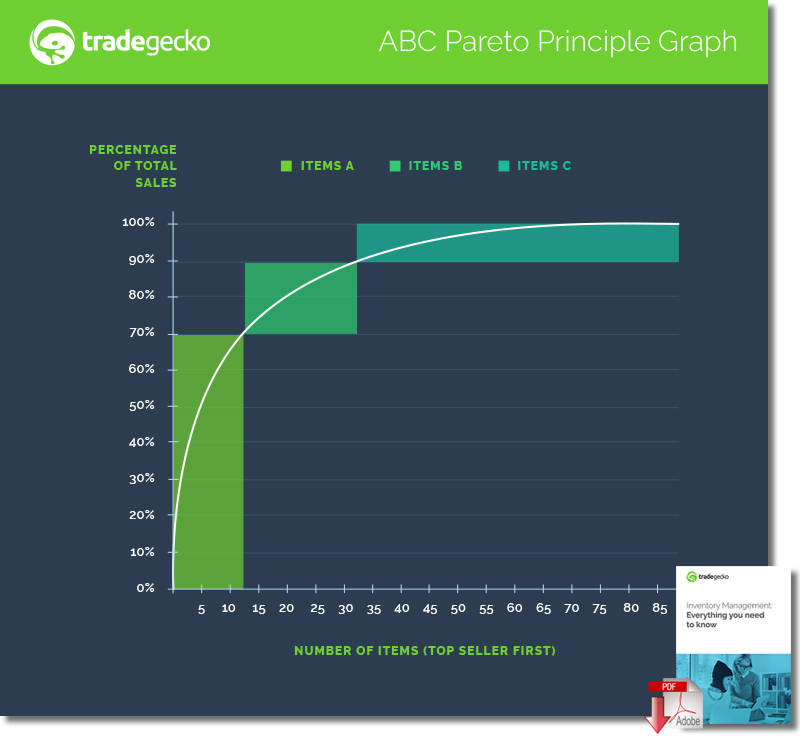

Product segmentation requites you to know your best and lowest sellers, and to apply this to your inventory. If you’re using inventory management software, this is going to be even easier, since intelligence reports can sort your products (and variants) according to highest (and lowest) sellers. Once you have that information, it’s time to do an ABC analysis and to sort your products accordingly.

- A-Items are the top sellers with high consumption values

- B-Items are of medium consumption

- C-Items have the lowest consumption values

In the graph, you’ll see the Pareto principle in action. This works on the assumption that 80% of consumption is based on 20% of the products.

When you’re deciding on your inventory levels for different items, knowing this will let you know how to organize your inventory.

For example, if you’re a retailer with both online and brick-and-mortar stores, you may have products that are “in-store only” (meaning they’re not available online), so you want those items sitting in your backroom instead of waiting in your warehouse two hours away. On the other hand, you might recognize that customers prefer to get bulky items delivered to their home rather than picking them up in store, and items like these should be stored in the warehouse.

Price Optimization

Price optimization offers a great way for a business to tweak their offerings across different channels so that they’ll be able to maximize their profit.

Many online stores offer free shipping, but if you’re offering free shipping on everything, you’ll find yourself occasionally spending more on shipping than you’re earning from every sale. You can consider increasing the prices to make up for shipping, but that could leave you with disappointed customers that are used to the original prices.

So instead of offering free shipping on everything, why not simply increase the free shipping threshold? By doing so, you’ll be giving customers an incentive to order more, increasing the average order value. On top of that, you’ll be able to compensate yourself for shipping costs with the extra revenue and profit.

Price optimization also hinges on the importance of setting a price floor and avoiding deep discounts. By setting a price floor, you’ll be able to ensure that you’ll never sell for cheaper than cost. Even if your competitors are engaged in a lowest-price-wins competition to win customers, it’s usually smarter to abstain from following suit. After all, the whole point of engaging in price wars is to force competitors out of the market even if it means making a loss.

Another option is to strengthen the brand identity and take it in a direction that allows you to charge a premium. For example, you can offer personalized customer service that’ll let customers shop with the reassurance that in the event products are missing or damaged, you’ll replace these at no extra cost and with minimal hassle for the customer.

What Does The Future Hold For Toys “R” Us?

The company’s chief executive has pinpointed the issues facing the company, but the main challenge lies in fixing the problems the ailing toy giant is facing.

But getting Toys “R” Us back on its feet involves more than patching holes in a sinking ship.

It needs to successfully move away from its image as a dated retailer selling plastic by the pound, and as children’s entertainment moves towards the digital, Toys “R” Us will need to muscle its way into the consumer electronics market as well.

Inventory Management White Papers

Inventory Management: Everything You Need To Know

Most people begin their inventory management journey with spreadsheets and paper, but it’s not easy to scale spreadsheets to keep up with your business as you start selling more and more! Download Now

Removing Barriers to Inventory Optimization

Implementing multi-echelon inventory optimization across the end-to-end, global supply chain creates previously unavailable trade-off curves that deliver higher levels of service at lower inventory cost. Download Now

Top Supply Chain Trend: Distributed Order Management

The purpose of a distributed order management system (“DOM”) is to intelligently broker orders across the various systems and processes utilized by the multiple parties involved in replenishing an order. Download Now

Eliminate 7 Wastes from Your Supply Chain with Real-Time Asset Management Solutions

By adopting lean manufacturing techniques, supported by Real-Time Asset Management Solutions, you can reduce and/or eliminate the seven wastes of manufacturing. Download Now

Article Topics

TradeGecko News & Resources

How Does IKEA’s Inventory Management Supply Chain Strategy Really Work? Inventory Management: Everything You Need To Know How Out-of-Stock Inventory is Killing Toys’‘R’‘Us The Long Tail of Inventory and Why It’s Important Incredibly Successful Supply Chain Management: How Does Walmart Do It? Inventory Management 101Latest in Supply Chain

Microsoft Unveils New AI Innovations For Warehouses Let’s Spend Five Minutes Talking About ... Malaysia Baltimore Bridge Collapse: Impact on Freight Navigating TIm Cook Says Apple Plans to Increase Investments in Vietnam Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility More Supply Chain